PCB Setting up - What You Required to Know

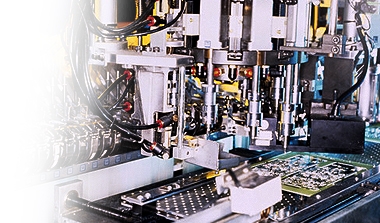

When you require specialist PCB Setting up service, there truly is only one business to resort to, which is PCBCart. Have a look at the complying with list of the premium PCB Assembly solutions provide: One-stop Manufacture as well as Assembly: A complete, full-service, high-end item setting up solution fulfills every one of your setting up demands.

Model PCB Setting up: PCB mini PCB's been available in various shapes and sizes, that make them very desirable for high quantity production. To make sure a smooth, durable procedure, the business supplies high-volume PCB assembly solutions. This helps them to maintain a limited grasp on price as well as service, while preserving a competitive price advantage.

Full Turnkey PCB Assembly Providers: Commonly firms find themselves collaborating with numerous various customers, each needing an one-of-a-kind technique to a distinct item. When collaborating with a full complete pcb setting up companies, you get every little thing you require under one roof. You'll obtain the circuit card layout, the elements, the packaging, the labeling, the documentation - all under one agreement. It's a win-win for every person!

Electronic Components PCB is made from a wide array of digital parts. They're used in every little thing from basic passive resistors to complex programmable logic gateways. Many digital parts come pre-assembled, however there are still times when something turns up. When this happens, it's frequently hard or impossible to find the exact component that you need. PCBs use a method to stay clear of wasting time looking for the appropriate component. PCB motherboard assembly makes it easy to transform or add elements to existing PCB's whenever you require to.

High-Performance PCBs: Many PCBs are made with either full PCB or direct PCB materials. With straight PCB products, you'll often see parts that have actually been layered through-hole technology. Through-hole innovation includes feeding components through specific openings in the PCB. Through-hole parts provide a higher level of precision than their plated counterparts. Along with being very effective, they can additionally be generated on a much larger scale. If you want the most effective high quality components, after that you need to go with the complete PCB.

High-Throughput Motherboard: PCBs that are produced with high-throughput motherboard are made for manufacturing functions. They&%2�,o339;re generally made use of for applications where a high degree of manufacturing is needed. Instances of applications consist of medical and industrial tools. Because they call for less product and a shorter production process, they're excellent for miniaturizing circuit boards. The reduced cost related to these elements makes them suitable for several small companies.

Inexpensive Electronic Parts: Although inexpensive components are excellent for miniaturizing as well as lowering manufacturing costs, they aren't constantly used the most reliable techniques. In many cases, the amount of money that you spend on a digital part offsets the lower quality. If you're servicing a smaller project, you may not have the cash to buy the most effective and also state-of-the-art setting up techniques. When you need to have your electronic tools generated quickly as well as at an inexpensive, then you'll often look to the PCB setting up route.

The manufacturing world has taken notice of what PCB suppliers are able to make with fine print motherboard. Because of this, the device is widely utilized. You can make use of pcb assembly when you want to have your digital devices produced as swiftly as well as effectively as feasible. Whether you intend to produce a prototype, make a run of hundreds or thousands, or assembled a number of devices that will interact, you can use this method of production.

Types of PCBs: There are two main selections of published circuit card, and also these are the bipolar and also the multistage. The bipolar variety of PCB has a collection of interconnected printed conductive traces. These traces are all soldered to a board. The multistage PCB, by contrast, consists of several PCBs which are connected in different configurations. They all link to a common PCB base. This sort of PCB setting up technique is a lot more intricate than the bipolar selection, as well as it is additionally extra costly.

Just How to Use PCB Assembly: In order to have reliable PCB setting up, there are a couple of points that you ought to understand. Initially, you must choose parts that are best suited to your project. The parts must be trusted and also durable, to make sure that they can stand up to the examination of time and also the atmospheres in which your digital tools will be used. It's additionally essential to pick elements that work well with each various other, to ensure that you can develop a practical as well as visually pleasing design. As soon as you've selected your parts, after that you can obtain the materials prepared, find a great PCB maker, and also buy your published circuit boards.

Assembling PCBs is fairly easy once you have actually developed a plan. A full complete PCB assembly can conserve you as much as 80% of expense over creating a physical item model from the ground up. By getting wholesale, you'll pay simply a fraction of the expense of creating a solitary item. Likewise, dealing with a highly-qualified and experienced PCB manufacturer makes certain that you get an exceptional quality assurance and also greater customer support. PCB manufacturers can provide PCB setting up wholesale to make your following electronic device a low-cost, high value success.

PCB Assembly - A Review

A Printed Circuit Board (PCB) is a paper, plastic element that is used in electronic products such as computer chips, cellphones as well as MP3 gamers. The published motherboard can be made to consist of different elements, such as resistors, transistors, diodes as well as electrolytes. The process of creating as well as developing a PCB calls for several steps.

PCB Assembly - The PCB Assembly just requires the components to be attached to one another, with the help of various devices. The most typical devices utilized in the setting up capabilities consist of push-fit adapters, soldering weapon, solder, soldering paste, zip tie as well as thermal tape. One more essential tool used for PCB assembly abilities is the plasma cutter, which is utilized to reduce holes for connection of the components. These tools are available at electronic devices shops and come in various price ranges. Numerous companies provide customized PCBs, in which the consumer can select the material and also the shade of the PCB. The consumer also has the choice of placing the logo design of the firm on the front side.

Quality Assurance Inspection - The major benefit of PCBs is that they give excellent quality electronic devices. The PCB quality kaizentechnology.co.uk/ evaluation techniques include aesthetic evaluation and also electric circulation testing. The aesthetic inspection of the pcbs involves inspection of the physical layer, aesthetic evaluation of the features and connection testing for right functioning. The electric flow testing generally examines the reliability of the electrical connections between the elements. A PCB might fail to fulfill the top quality criteria if any one of these https://www.washingtonpost.com/newssearch/?query=PCB Assembly elements are not working appropriately.

Electronic Components as well as Mounting Solutions - The digital parts as well as PCB mounting systems make the general PCB assembly procedure simple. Previously, the only means to put devices and also parts was to make use of copper sticks. After that, the technique of parts and tools positioning ended up being preferred in the 1970s. This popular method of component positioning included exploration holes via the components making use of an epilator tool. Later on, digital component companies started making use of surface area install innovation for the function of making the PCB.

Substrate Mounting Modern Technology - A PCB Assembly takes advantage of a selection of various sorts of substratums for the purpose of making the gadget. Copper, aluminum, plywood, acrylic and also various other artificial materials are extensively made use of for the objective of developing PCBs. The substrate is placed directly over the circuit boards as well as various components. Later, the pattern of making use of SMT technologies came into existence and these are extensively utilized in the area of PCB assembly.

Inspections and also Examining - Before PCB Setting up, a detailed inspection of the elements is needed for detailed screening. Different sorts of tests are performed for examining the effectiveness of the device and the overall performance. The assessment of the board surface area is finished with the aid of UV light, microscope and various other evaluation tools. There are several companies that contract the solutions of a PCB supplier who can conduct the assessment job and provide warranties for the capability of the product. In some cases, a testing laboratory is additionally set up to test the product as soon as it has been completed and also awaits assembly.

Assembly Process - The main objective of PCB assembly is to provide maximum advantages to the customers by lowering the price of production. This is done by raising the rate of production, guaranteeing regular top quality of the item as well as general satisfaction of the client. PCB setting up is generally performed in "plug and play" systems where all the parts are attached to each other with the aid of adhesive. After the glue is chosen to the PCB surface area, a circuit board is made to suit the open end of the element and also near to the solder paste stencil. The whole setting up process is finished within a period of 1 day time.

The major benefit of utilizing a PCB Assembly production is the decreased prices and also increased rate of production. It has actually been observed that the price of making a PCB with components connected as compared to the instance of making a put together one is around 30% much less than the case of a constructed one. In addition to this, the assembly procedure itself is likewise very simple and does not take wish for the product to be produced. One additionally require not bother with the compatibility with numerous software application. The majority of leading digital firms utilize PCB Assembly as a technique to create the finished items from excellent quality, reusable elements, which is both economical and secure. It is observed that the PCB setting up procedure is now made use of for manufacturing of lots of tiny to tool sized electronic products, which are made use of for individual and also specialist objectives alike.

PCB Assembly - How Do We Provide a Warranty for Your PCB Setting up?

There are three significant steps involved in PCB Setting up - selecting the right part(s), using solder and then connecting the element(s) to PCB. Each of these actions is outlined below carefully. Picking the Right Component The really first step entails picking the right element(s). Right here, it is advisable to pick the element that is highly suitable with the PCB supplier's specs.

For the parts, it is suggested to make use of plating makers or choose & position systems. Plating makers supply a good mechanical and chemical assistance. They also provide the ability to position components on any kind of surface. On the other hand, choice & location systems involve making use of equipments as well as numerous techniques such as bow based directing, and so on to place components on the PCB.

The 2nd step is the application of the final evaluation on the PCB setting up process. This includes the confirmation of the alignment, proportion and also shade. It is advisable to examine the existence of discontinuities, overprinted locations, and also various other abnormalities. Once the final examination is done, the pcb assembly awaits delivery.

The 3rd and last step involves PCB Assembly as well as the shipment of the completed item. To guarantee the quality of the finished item, one-stop stores utilize one-stop systems. This implies that they only deliver to one client. The entire process is finished from the sourcing of the elements, to the final examination as well as delivery of the final product.

The main advantage of making use of one-stop PCB setting up process is that it saves time, effort as well as cash. The moment aspect includes the moment needed to look for an excellent supplier, for figuring out the best rate for the materials required for the production process, for establishing the production line and also for providing the final product. This takes away the time required to go from design to fully developed PCB setting up. Likewise, the price saving can help firms minimize the variety of contracting out orders they get. With one-stop PCB setting up procedure, you can additionally anticipate far better top quality result of same-quality, if not better, than you would have done previously.

The fourth benefit is that it permits business to conserve cash on labor costs. The automation of the PCB assembly removes the need for experienced personnel that are available just in huge firms. Instead, it is possible for a solitary employee to look after the entire manufacturing procedure, from layout to mass production. This would have been difficult with the standard PCB production.

The following advantage is that you can obtain a top quality pcb setting up made even for low-cost electronics. You need not worry about pricey PCB production procedure since you can utilize the solutions of a specialist PCB supplier such as us. We can utilize our experience in choosing the best sort of PCB materials and also in developing the right sort of PCB setting up.

Ultimately, you can get a completely put together, quality-controlled, ready to use PCB setting up for a fraction of what it would cost you to have it done commonly. Our group is constantly on the look out for brand-new methods to improve our solutions. If you have a new idea or want to alter the way you do business, we are right here to pay attention and also help. Our PCB suppliers will certainly always have the ability to see what you need to use. So, call us today to see just how much we can assist you. If you have any concerns, no problem - we're right here to help you anytime you require it.

One other advantage that we can attend to you is that we can supply you with an on-site evaluation of your PCB assembly. Whether it's brand new or old, we can check it for problems utilizing state-of-the-art tools such as x-ray, wetness detectors, as well as wetness probes. By doing this, we can make sure that all parts are working properly. We can likewise give you with a quick on-site replacement of the defective components are no longer available.

The last benefit is that we can make certain that you don't experience PCB failing throughout the last examination. There are numerous circumstances when the PCBs we produce http://www.bbc.co.uk/search?q=PCB Assembly bend, fracture, and also break as a result of incorrect soldering process. However, as we understand also well, these issues are avoidable by seeing to it that the soldering procedure is done according to the requirements of the client. By having an on-site inspection, we can eliminate these potential dangers. And if there is a PCB failing, the final assessment will certainly reveal that we made the required improvements so the item will operate appropriately.

With our PCB assembly solutions, you can be assured that we will always do whatever possible to make certain that your items will show up in its best condition. To be able to offer you with a 100% assurance on the last inspection of your item, we will certainly purchase the most recent technology made use of in circuit boards such as the PCFide and also PCBS products. Along with that, we will also supply you with a solution that makes certain that we can supply you with rapid turn-around times for your PCB's, making the procedure versatile for your business needs.</