A PCB Setting up is a circuit card made of plastic or resin on which electronic devices as well as various other data are packed. The parts of a PCB Assembly are printed circuit card. The PCBs are made through a selection of different techniques, including desktop-based computer system assisted style (CAD) systems and automated procedure techniques. In electronic devices, the PCBs play a substantial function in the digital gadgets. The PCBs are utilized to develop the exterior of electronic tools, in addition to inner components like circuits, integrated circuits and various other programmable reasoning devices.PCB Setting up

is done via two different types of techniques. The first type of method is known as through-hole technology, while the 2nd sort of method is known as layered through-hole modern technology. The through-hole technology entails publishing the parts on PCB's with opening slots that have been pierced by hand utilizing a blowpipe. On the various other hand, the layered through-hole innovation involves publishing the elements on the PCB through opening ports that have been offered by the producer. These elements are then soldered together with the assistance of solder.The appeal of printed circuit card assembly has actually resulted in its use in a wide range of digital devices worldwide. It is widely used in clinical devices and also commercial devices, consumer products and also electrical equipment, auto devices and also mechanical components of autos. Furthermore, it is commonly utilized in numerous aspects of production, particularly in the manufacturing of electronic components for electronic devices playthings as well as video games. In electronics, it is commonly made use of to create the bodies of electronic electronic cameras, computer systems as well as various other digital devices.The PCBs are additionally used to develop the insides of computer systems as well as other digital devices

. A PCB is typically made from 2 significant components. These parts are the printed motherboard (PCB )as well as the PCB substratum. The PCBs are normally published with a selection of products including PCB material, conductive traces, solid-state diodes, silk lamination, etc.The published circuit board's( PCB )surface area might be made of a variety PCB Assembly company of materials such as timber, aluminum

, plastic, fiberglass, etc. The most preferred PCB product is published motherboard(PCB )paper. Normally, the density of the PCB material is four to 6 millimeters; nonetheless, it can additionally be as slim as one micrometer.In addition, published circuit board (PCB )production calls for the use of a selection of techniques to produce distinct PCB styles.

Some of these methods consist of warmth sinking, etching, UV coating, etc. While developing PCBs, one have to guarantee that the overall location of the boards ought to not much less than 300mm. This is to guarantee that the motherboard will be compatible with each various other. Additionally, you have to also make sure that the boards can support high present capacity.The PCB manufacturing procedure typically includes the assembly of different PCB elements. One of the most typical elements are resistors, capacitors, ICMs, transistors, and also diodes.

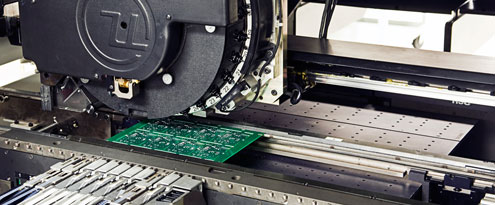

At this stage, the PCB is planned for the production process. Throughout this time, the PCB is positioned on a warm sink or PCB stand. This is done so that the components can be put in the preferred setting. In addition, the PCBs are also wired together.After the components have actually been put in the preferred settings, the PCBs are then examined. If the components function appropriately, then the PCB awaits being printed on. The published motherboard (PCB)production then begins.During the PCB manufacturing, a number of steps are accomplished. Firstly, a picture of the PCB is produced making use of computer system software application. Next off, the photos are moved on the PCB utilizing a warm transfer method. Finally, the PCB is published using ink rollers

. The printed circuit board then appears as finished PCB. This whole process can take couple of weeks to complete.However, the printed circuit process is not complete if the ports are not installed. The port assists in link of the PCB to different devices. The other essential point is the screening of PCB. The screening procedure of PCB guarantees the dependability of the gadget.However, the printed circuit procedure is very technical. Hence, some of the companies offer aid to individuals involved in the procedure. A number of these business provide cost-free recommendations as well as training on how to construct and also create PCB. You can get details from these firms. Additionally, you can also find PCB Assembly and PCB Evaluating solutions online.